Founded in 1996 as a product development and tour support specialist for clients in the music industry, Futureshirts has grown into a full-service entertainment merchandising company. Today, the Nashville, Tennessee-based wholesaler and marketing specialist offers retailers a menu of boutique services—everything from product development, on-site support, and e-commerce solutions to fulfillment/logistics.

Over the years, demand for Futureshirts’ fulfillment and logistics services has taken off, putting stress on its back-end operations. As order volumes continued to build, company leaders decided it was time to embrace automation. After reviewing their options, they decided to take the software, as opposed to hardware, route and began searching for a comprehensive solution that would optimize every aspect of Futureshirts’ fulfillment process—from managing inventory and improving order processing to enhancing labor management.

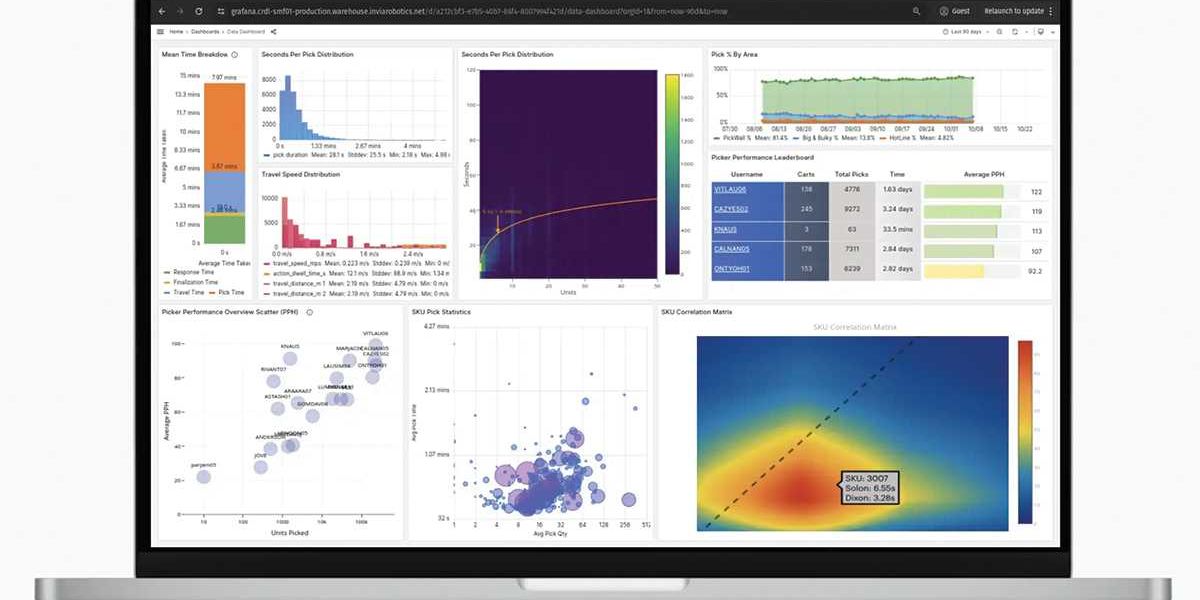

Futureshirts’ search led it to inVia Robotics, a Thousand Oaks, California-based developer of AI (artificial intelligence)-powered warehouse automation software. After consulting with its new partner, the wholesaler deployed inVia’s intelligent automation platform, which uses decision intelligence, dynamic scheduling, and data visualizations to help clients enhance and streamline their fulfillment operations.

INTELLIGENT AUTOMATION IN ACTION

Today, Futureshirts is using the inVia Logic warehouse execution system (WES), the inVia Logic Replenishment module, and the inVia PickMate productivity tool at its facility in Nashville. And the results have been game-changing, the two companies say.

The centerpiece of the new system is the Logic WES, which makes more than 1 million decisions each day to orchestrate all of the resources in the facility—telling operators what to do, when to do it, and where inventory should be located. The system also coordinates workflows across picking, replenishment, and inventory management, continuously reassessing priorities and reallocating resources to maintain peak performance. As a result of the optimized workflows, Futureshirts has seen a 500% increase in pick rates, the companies said in a recent case study.

The wholesaler has seen similar results with the inVia Logic Replenishment module, which dynamically triggers replenishment based on order volume and threshold values, ensuring inventory is available where and when it’s needed. Implementing this module has allowed Futureshirts to reduce restocking time from days to hours, according to the case study. It has also enabled real-time synchronization between the e-commerce front-end platform and warehouse inventory, which has led to faster and more accurate order processing, the companies said.

And on the warehouse floor, the inVia PickMate productivity tool has transformed the onboarding process with its intuitive interface and step-by-step guidance for pickers, according to the developer. Employees quickly adapted to the system, which has reduced training time from two weeks to just one hour. On top of that, inVia PickMate has significantly reduced mispicks—bringing order accuracy to virtually 100%, according to inVia.

Futureshirts has seen other benefits as well. For example, it has gained real-time visibility into its warehouse performance through inVia’s advanced dashboards and reports, which provide actionable insights into labor productivity, daily fulfillment progress, and inventory control. And by using the system’s 3D modeling capabilities, the wholesaler has optimized its inventory placement and pick zones, making items easier to access and further improving workflow efficiency.