Australian investigators have revealed that a Qantas Airbus A380, registered as VH-OQI, flew for more than 290 hours with a tool inside one of the engines before it was found again during regular maintenance.

Borescope inspection

In a report the Australian Transport Safety Bureau (ATSB) published on November 14, the investigators detailed an event when maintenance engineers left a tool inside the outboard left engine on a Qantas A380.

According to the report, the aircraft involved in the foreign object debris (FOD), an A380, registered as VH-OQI, underwent line maintenance procedures at the Australian carrier’s facilities at Los Angeles International Airport (LAX) on December 6, 2023.

The three-day maintenance visit included a borescope inspection of the left outboard engine’s intermediate-pressure compressor.

Photo: Ryan Fletcher | Shutterstock

“The borescope inspection was to be conducted on day one and was estimated to take approximately 6 hours.”

The ATSB highlighted that initially, a licensed aircraft maintenance engineer (LAME 1) assigned two AMEs, AME 1 and AME 2, as well as a support engineer, to conduct the borescope inspection. The two AMEs collected the required managed – meaning administratively allocated – tooling for the task, including a nylon rod, also known as a turning tool.

“The support engineer entered the engine inlet via the access stand and rotated the engine’s intermediate-pressure compressor, as required, using the turning tool.”

However, AME 1, who signed out the tooling and was present during the initial phases of the borescope inspection, left work early for a medical appointment and was not rostered to come back in for three more days.

Photo: Markus Mainka | Shutterstock

Subsequently, when AME 2 inquired whether the managed tooling needed to be returned to the tool store, LAME 1 told the engineer to leave the tools for the incoming afternoon shift, which began work at 15:00.

LAME 1 stayed at work because the borescope task was unfinished, and two new engineers, AME 3 and AME 4, as well as the supporting engineer who was with AME 1 and AME 2, continued the inspection.

Related

Route Analysis: The Current State Of Qantas’ Airbus A380 Network

South America is the only continent where Qantas doesn’t offer services on its A380s.

However, the supporting engineer provided guidance to AME 4 on how to use the turning tool and departed the site.

“AME 3 completed the inspection operating the borescope and asked AME 4 if they wanted to view the images prior to reinstalling the borescope access plugs on the engine. AME 4 left the turning tool in the inlet, as they believed it would be used again later, and proceeded out of the inlet down to the ground to view the borescope images.”

At 18:00, which was after dark at that point, LAME 1 asked AME 2 to return the tooling used for the task. As a note, AME 1 signed out the tooling for the borescope inspection.

AME 2 proceeded to inspect the inlet cowl to check for any tools and found a protective mat, which was removed and returned to the tool shop. Despite it being after dark, AME 2 did not use a torchlight.

“LAME 1 conducted the first inspection of the completed borescope task, and also conducted a foreign object debris check of the inlet using a torch but did not detect the turning tool.”

Source: ATSB

Afterward, LAME 2 conducted another independent inspection at 21:00. However, while the engineer checked the borescope access plugs and the engine lower area, they did not inspect the inlet cowl, where the turning tool was left.

LAME 3, not involved in the borescope inspection, was performing end-of-shift task closure duties and noticed that the turning tool was missing. AME 1 proceeded to tell LAME 3 that when he left work, the tool was still in use.

On day two and day three of the A380’s maintenance at Los Angeles International, the turning tool remained unaccounted for, and on the latter day’s evening, at 23:36, the A380 departed the US for Melbourne Airport (MEL).

On December 10, four days after the tool was left inside the engine inlet cowl, LAME 1 raised a missing tool report against the airframe. The required follow-up process was not commenced, the ATSB noted.

Photo: Ryan Fletcher | Shutterstock

On January 1, the A380 returned to Los Angeles for the fourth time since December 6, 2023. The aircraft was scheduled to undergo maintenance, which included a detailed inspection of the low-pressure compressor (LPC) on all four engines. Only then were the responsible engineers able to find the tool, return it to the tool store, and physically quarantine it (not available for use pending investigation).

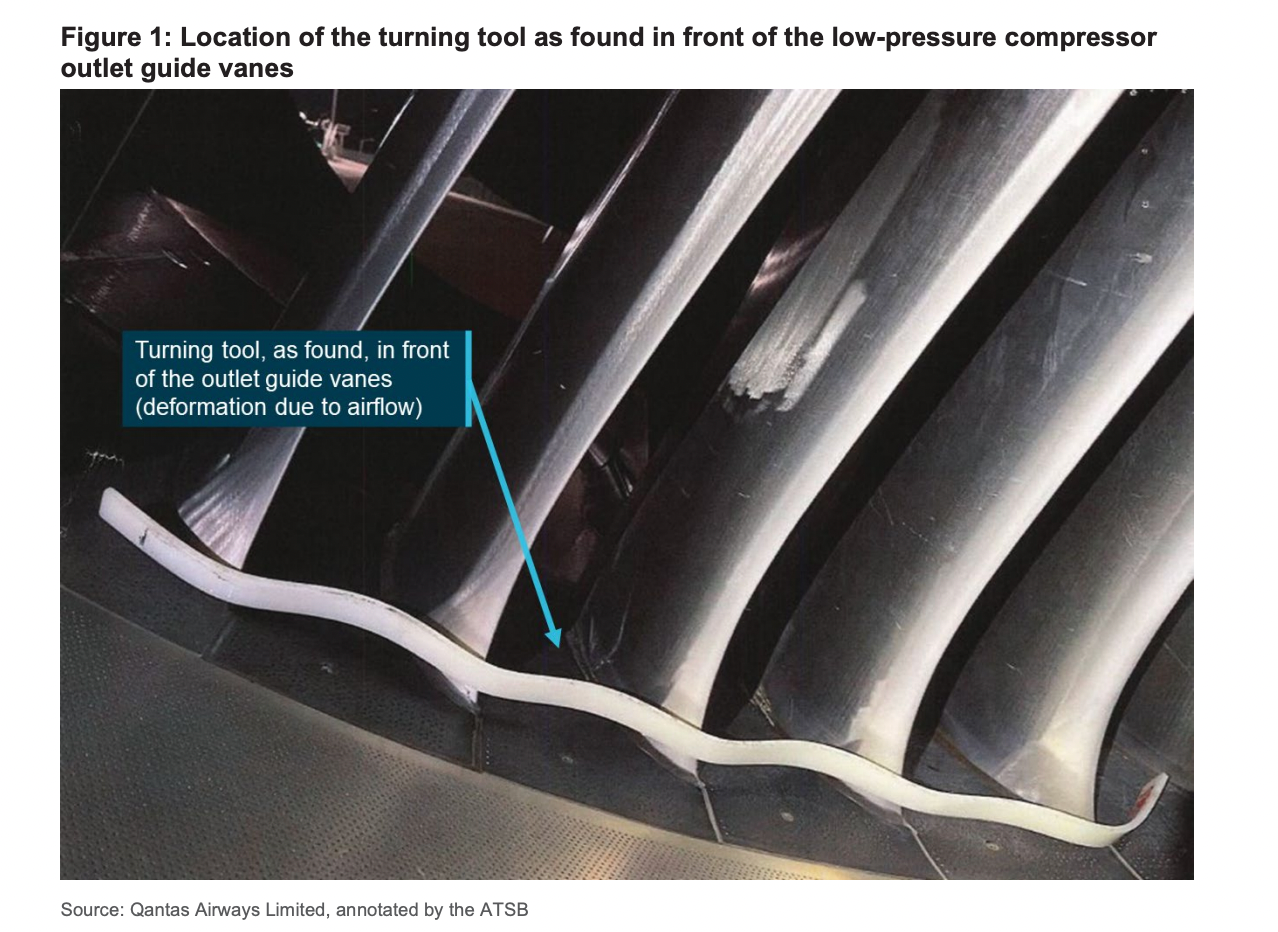

The turning tool was found behind the rotating LPC blades. The ATSB highlighted that high energy airflow around the LPC outlet guide vanes deformed the tool. However, the engine remained unharmed.

Related

Qantas Confirms Superjumbo Airbus A380 Return To Dallas/Fort Worth In 2025

It comes after a five-year-plus absence.

Flying 34 cycles and over 290 hours

The ATSB highlighted that before it landed in Los Angeles on January 1, the A380 operated 34 flight cycles (FC) and 293.74 flight hours (FH) with the turning tool inside the engine.

“It is likely that this is where [wedged against the LPC outlet guide vanes – ed. note] the tool was left as, if the turning tool was left in front of the low-pressure compressor, it would likely have displayed more damage from passing through the rotating low-pressure compressor blades during engine operation and been more visible to AME 2 and LAME 1 during their foreign object inspections.”

The Australian investigators noted that AME 2, the support engineer, and AME 4’s unfamiliarity with the task, AME 1 leaving work early, re-tasking AME 2 to other duties, and LAME 1’s advice to leave the tools without a return and re-issue of the tooling for the next shift likely affected the engineers’ sense of ownership and accountability for the turning tool.

Photo: Tupungato | Shutterstock

The ATSB outlined three contributing factors that led to the turning tool being left inside the engine of the A380:

- Maintenance engineers’ failure to observe the tool during their post-maintenance FOD inspections

- The failure to commence the lost tool procedure

- A service engineer issued a certificate of release (CRS) despite the tool being unaccounted for.

In response to the incident, Qantas took two safety actions. On January 2, an internal incident report was raised, briefing staff about the importance of ensuring that all tools are returned and actioned by the tool store personnel.

On March 4, the executive manager of Qantas Engineering released an internal safety directive, prompting immediate action for all of the airline’s engineers to meet the requirements of tooling control.

Photo: Qantas

The ATSB first notified the public of the incident in February, saying that it was investigating an incident related to a tool being found inside the engine of an A380.

VH-OQI has remained in active service with the airline. Most recently, it operated a flight from Sydney Airport (SYD) to Singapore Changi Airport (SIN) before continuing its journey toward London Heathrow Airport (LHR) on flight QF331, which is not the usual Kangaroo Route flight code QF1.

Related

Tool Found At LAX In Qantas Airbus A380 Engine After 1 Month Missing

Australian investigators have disclosed that mechanics found a tool inside a Qantas Airbus A380 engine after it has been missing for a month at LAX.