Support CleanTechnica’s work through a Substack subscription or on Stripe.

Or support our Kickstarter campaign!

Sodium-ion batteries have been lingering around the fringes of the vehicle electrification movement for years. A breakthrough moment has finally arrived as the hurdles to commercial application have fallen. Even so, science never sleeps, and researchers are already on the hunt for further improvements.

Solving The Hard Carbon Problem, Part 1.

The sodium-ion battery formula has some advantages over conventional lithium-ion batteries, including the use of nonflammable, abundant materials and the potential for cutting costs. Reducing the weight for use in EVs has been a key obstacle, which explains why some innovators in the field have been focusing on stationary energy storage applications. The mobility nut is beginning to crack as well. The well-known Chinese firm CATL launched its first market-ready sodium-ion batteries in 2021, and in 2023 the lesser known up-and-coming Chinese startup HiNa introduced a micro-car powered by sodium-ion batteries.

CATL further leveled up the game early this year, announcing that a sodium-ion battery for EVs with 310 miles of range will be in commercial production soon.

Still, there is always room for improvement, and one of those rooms is the anode materials. The graphite used in lithium-ion batteries is not a candidate because it can’t store sodium. The consensus alternative has been hard carbon, a form of carbon that doesn’t devolve into graphite under high heat.

Hard carbon can inhibit capacity during the anode formation stage, when the battery is being manufactured. However, CATL has evidently resolved the hard carbon problem to its own satisfaction.

Solving The Hard Carbon Problem, Part 2.

CATL or not, researchers continue to search for alternative anode materials. One recent example to surface comes from a team of researchers at BAM (the Federal Institute for Materials Research and Testing) in Germany.

The BAM team notes that the loss of capacity during the manufacturing process is the result of a chemical reaction between the electrolyte and the anode. “During this process, electrolyte molecules decompose at the hard carbon anode and penetrate its pores,” the researchers elaborate. “They occupy ‘empty spaces’ that are actually intended for the storage of sodium ions. This process only comes to a halt once a stable protective film has formed on the anode.”

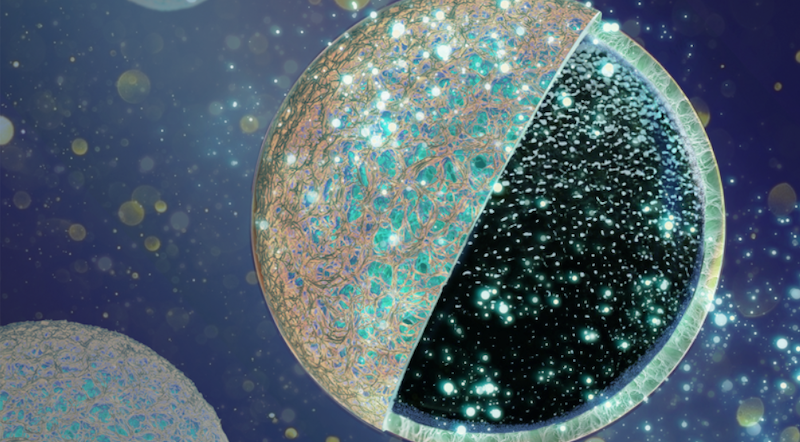

The BAM solution involves a customized form of activated carbon, applied over a core of sponge-like hard carbon in a thin layer. Activated carbon is commonly used as a filter, and that’s what it does here, allowing sodium ions to reach the hard carbon core while keeping the electrolyte out.

“The materials developed in the study already achieve an initial efficiency of 82 percent — without coating, it is 18 percent,” the team summarizes, referring to the results posted in the journal Angewandte Chemie.

The Battery-Swapping Angle

And, here’s where things get interesting. Because sodium-ion batteries are non-flammable, they are more amenable to the intersection of mobile and stationary energy storage systems — namely, battery swapping.

EV battery swapping has failed to gain traction here in the US, which is understandable considering that Tesla CEO Elon Musk dismissed battery-swapping after conducting a somewhat lackluster trial back in 2013. Nevertheless, other markets picked up the ball and ran with it (see lots more battery swapping background here).

Battery swapping stakeholders have also begun to tap into the multi-use potential of swapping stations. In addition to providing EV drivers with a freshly charged and vetted battery in a matter of minutes, batteries at the station can pull duty for grid reliability and emergency response, just like any other stationary energy storage system.

Of course, lithium-ion batteries do stationary energy storage, too, and they are doing it quite well. However, the non-toxic, non-flammable electrolyte in sodium-ion batteries is an advantage, particularly in crowded urban environments where fire safety is a concern.

That brings the circle back around to CATL. As recently noted by CleanTechnica’s Steve Hanley, CATL held a supplier conference on December 28 in which the company said that “sodium batteries will see large-scale adoption in battery swapping, passenger vehicles, commercial vehicles, and energy storage” in 2026.

Sodium-Ion Batteries Are Coming For Your Fossil Fuels

Don’t just take our word for it. On January 12, MIT Technology Review conducted a state-of-the technology review under the headline, “A cheaper, safer, and more abundant alternative to lithium is finally making its way into cars—and the grid.”

In addition to CATL, MIT reporter Caiwei Chen takes note of HiNa, which is now applying its sodium-ion formula to low-speed EVs. The Chinese firm JMEV also gets a mention, for offering a sodium-ion option in its EV3 city car. Also in China, the firm Yadea began selling two-wheelers with sodium-ion batteries.

Still, as Chen emphasizes, the most immediate and significant impact is on the stationary storage side for grid purposes, drawing attention to the US startup Peak Energy.

In that regard, keep an eye on the goings-on over at the US Department of Energy, where the Pacific Northwest National Laboratory is hosting the Grid Storage Launchpad, aimed at bringing new utility-scale energy storage systems to the grid, more quickly. The Launchpad opened for business in 2024 and was still up and running last year, despite the sharp U-turn in federal energy policy.

As for what happens next, your guess is as good as mine. Still, on January 13, GSL announced that it has expanded its battery testing capabilities. “PNNL has offered testing capabilities to companies for smaller batteries for several years and is now ready to begin testing larger systems,” the lab explains. “GSL experts can test batteries that use a variety of chemistries, such as lithium-ion, sodium-ion, iron, or lead-acid.”

The sodium-ion angle is particularly interesting due to PNNL’s longstanding sodium-ion battery research programs, which are hopefully still standing. In 2024, the lab was tasked with spearheading the new “Low-cost Earth-abundant Na-ion Storage” consortium. “LENS is a major research and development effort to create superior, no-compromise batteries that replace lithium with inexpensive, domestically abundant sodium and use few—if any—critical materials,” the lab declared in an update last July.

“As one of the world’s leading producers of sodium-rich compounds, the United States is exceptionally well-equipped to supply the raw materials for sodium-ion batteries,” PNNL emphasized.

“A battery supply chain based on domestic sodium rather than imported critical materials would be more resilient and give the United States a competitive edge in the global energy storage market,” they added again for good measure.

Fingers crossed….

Image: Researchers are developing new materials to improve the performance of sodium-ion batteries for stationary energy storage and EVs, too (shown here, an outer layer protects the core of the carbon anode, courtesy of BAM).

Support CleanTechnica via Kickstarter

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy