Support CleanTechnica’s work through a Substack subscription or on Stripe.

Carbon capture and storage has been marketed as a general solution to climate change. The record shows it is not. Where it does make sense is where chemistry gives you a high-volume, concentrated stream of CO2, where geography puts that stream on top of storage or at a pier with pipeline routes offshore, and where policy puts a real value on abatement. Everywhere else, CCS is outcompeted by electrification, efficiency, process substitution, or stopping the emitting activity. The point is not to dismiss CCS. The point is to use it only where it is the lowest cost path to real emissions cuts.

Purity is the first filter. Capture from dilute flue gas is an energy and money sink because you are separating a small fraction out of a big inert stream. Fermentation off-gas from ethanol production is almost pure CO2 with water vapor and trace organics. Dry it, compress it, inject it. Steam methane reforming in ammonia plants makes hydrogen and a high CO2 stream that is already separated in the process train. Lime and cement kilns release CO2 from calcination of limestone. If you engineer the heat source and gas path correctly, you can keep that process CO2 relatively clean of combustion products. Biogas upgrading splits methane and CO2. The CO2 side is close to pure. In metallurgy, direct reduction of iron using biomethane produces concentrated CO2 streams that can be compressed and stored without the costs of scrubbing flue gases. These are the places where capture is not a giant chemical plant bolted on top of another plant. They are housekeeping steps on streams that already exist.

Location is the second filter. Every kilometer of pipe and especially every non-pipeline pathway adds cost and public risk. On-site injection into proven saline formations solves both if the geology cooperates, as in Illinois and North Dakota. Waterside plants with short pipelines to offshore storage, as around the North Sea, can also be sensible. Trying to build continent-spanning liquid CO2 networks across cities for low-purity sources is not. The economics collapse under capital, compression power, right-of-way fights, and safety engineering. Good CCS projects look boring on a map. They sit next to their sinks.

Policy is the third filter. A project lives or dies on the value per ton. If capture and storage from a pure stream can be done near or below the combined value of the carbon price, credits for removals, and any targeted support, and is cheaper than alternatives, it pencils out. If not, it will struggle in a market that is full of other ways to cut emissions. This is why the early movers are almost all in the easiest categories with public support, not in general fossil combustion.

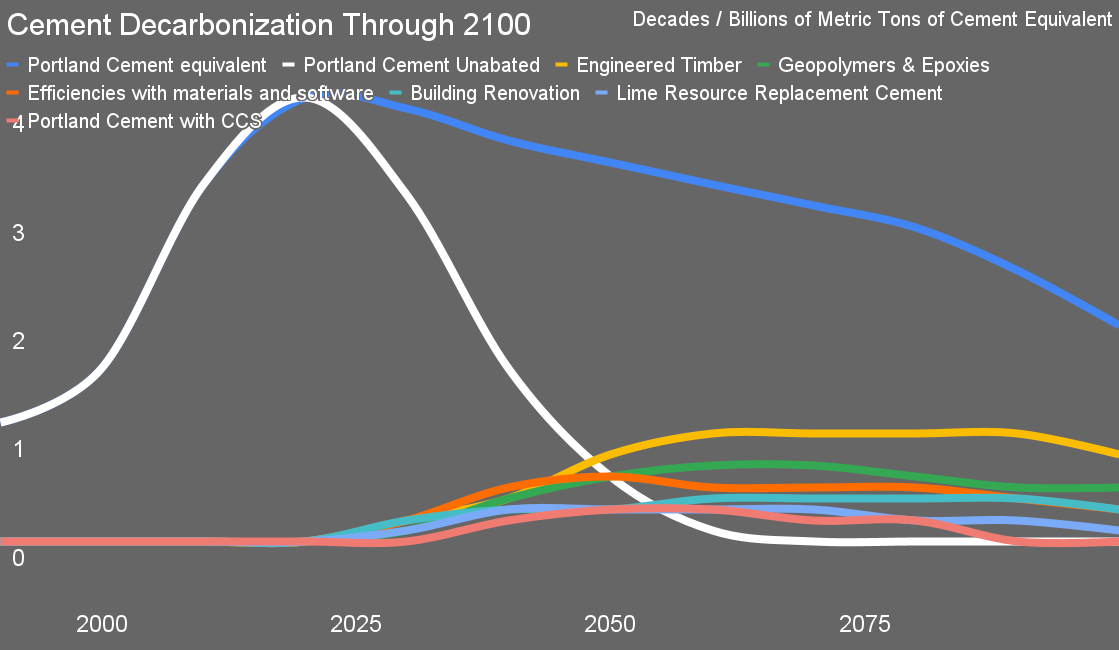

That’s why my projection of cement demand through 2100 shows relatively low amounts of cement with CCS. We have a large number of alternatives to cement, and most of them are cheaper than cement with CCS in most locales, leaving little opportunity for CCS.

Ethanol fermentation is the cleanest CCS niche. The chemistry is simple. Yeast converts sugars to ethanol and CO2. The off-gas is nearly all CO2. Plants that sit over good storage or within short connection distance can dehydrate and compress that stream and put it underground. Where there are crediting regimes that reward lower fuel carbon intensity, capture pays back through higher product value in addition to any storage credit. It is also one of the few cases where you get a biogenic stream that can be counted as carbon removal when stored. The competition is not another CCS project. The competition is failing to qualify for low carbon fuel markets or spending more for the same carbon result with a much more complex technology.

The United States burns about 25 billion gallons of jet fuel each year, while its ethanol plants produce roughly 16 billion gallons of corn-based ethanol annually. If all of that ethanol were diverted through alcohol-to-jet conversion, it could yield about 9 billion gallons of sustainable aviation fuel, or roughly 35 to 40% of current jet fuel demand. That makes ethanol one of the most obvious feedstock wedges for aviation decarbonization in the United States, the most aviation-heavy country in the world. The gasoline blending market that once absorbed almost all U.S. ethanol is shrinking as battery-electric vehicles replace internal-combustion cars, eroding the traditional offtake for corn ethanol. Yet the industry itself will not disappear — tens of billions of dollars in agricultural, processing, and logistics systems are built around it. Bipartisan support exists for subsidies for farmers, or at least the subject is a political third-rail that no party will touch. As domestic road fuel demand fades, alcohol-to-jet emerges as the logical destination for that output, turning a declining ground-transport fuel into a critical enabler of cleaner flight.

Ammonia and fertilizer plants also fit. Conventional ammonia uses natural gas reforming for hydrogen. That yields a large, concentrated CO2 stream during shift and CO2 removal, historically used to make urea or vented. Waterside plants can liquefy and ship to offshore storage. Onshore plants near basins can connect by short pipe. In the medium term, green hydrogen threatens the long-term business case for blue ammonia in some markets, but during the transition capturing an existing pure stream at a plant with the right geography is a rational bridge. The relevant comparison is not to hypothetical zero cost green hydrogen. It is to the actual cost and timeline of replacing entire hydrogen trains while meeting current fertilizer demand. While in my projections ammonia fertilizer demand — the largest off-taker — will decline due to a variety of agricultural transformation levers, we will still need a lot of ammonia, and once again, if biogas is used as a feedstock instead of fossil methane, the CO2 stream is biogenic and would count as actual atmospheric carbon drawdown.

Methanol production is another industrial process that deserves attention in the discussion of carbon capture because of the way it naturally creates a concentrated stream of CO2. In conventional plants using natural gas, the feedstock is reformed at high temperature to make a mixture of hydrogen, carbon monoxide, and carbon dioxide that is later balanced and converted into methanol. The process involves deliberately removing some CO2 to fine-tune the gas blend, which means that a clean and steady stream of CO2 already exists before any capture equipment is added. When the carbon source is biomass instead of fossil methane — such as biogas, wood waste gasification, or black liquor from pulp mills — that CO2 becomes biogenic. Modern plants that turn biomethane or gasified biomass into methanol can therefore capture and store a large fraction of their carbon without major redesign. Because the CO2 is already concentrated and under pressure, the extra cost of capture is modest, generally similar to that of fermentation plants. If that CO2 is stored rather than released, the resulting methanol can become genuinely carbon-negative. This makes methanol manufacturing with biomass feedstocks one of the most practical candidates for CCS, combining a useful fuel or chemical with a stream of process CO2 that can be permanently removed from the atmosphere.

Cement and lime are harder, but still within the niche definition if you re-engineer the process. The problem is not fuel. It is rock. Heating CaCO3 drives off CO2 and leaves CaO. If the kiln uses electricity or clean fuel and the calciner path is designed to keep the process CO2 separate from combustion gases, you get a higher purity stream that is much cheaper to capture than conventional post-combustion on mixed flue gas. Early full-scale projects show that even then capture is not cheap, but there are few alternatives that address the same fraction of emissions. Novel binders and clinker substitution are advancing and should be pursued in parallel. Where geology and ports make storage practical, CCS on the process stream can take a meaningful bite out of emissions while alternatives scale.

Biomethane direct reduction of iron is another candidate for selective CCS. In this process, biogenic methane is reformed to hydrogen and carbon monoxide to reduce iron ore to iron, releasing CO2 as the carbon carries oxygen out of the ore. Because the furnace off-gas is hot, pressurized, and relatively concentrated in CO2, it can be cooled, separated, and compressed with lower incremental cost than the mixed exhaust from blast furnaces. If the methane feedstock is biogenic, the resulting CO2 is biogenic too. After water removal and purification, the CO2 stream reaches sequestration-grade purity. The process fits only where cheap biomethane and nearby storage coincide, such as in parts of Northern Europe. Capture and compression costs are likely $50–60 per ton, storage another $30–40. Under EU carbon valuations this can close the economics if subsidies bridge the remainder. It is a transitional pathway, potentially carbon-negative on paper, but likely to give way to hydrogen direct reduction once renewable hydrogen becomes inexpensive. It still illustrates the same CCS pattern: chemistry that creates a concentrated CO2 stream, geography that offers short transport, and a carbon value that pays for storage.

When I was working with Tennet in the Netherlands this summer on a realistic 2050 energy scenario for the country, this is exactly the pathway we envisaged for Tata’s Rotterdam integrated steel plant. They are replacing one blast furnace with natural gas DRI, and we saw them displacing the fossil methane with biomethane, something already produced at scale in the country. The alternative they were considering was hydrogen DRI, but there is no economic pathway for that to compete where biomethane is available, so we chose the rational economic choice. Similarly, we saw the other blast furnace move to biomethane DRI as well, although we did discuss the likelihood that reduction of iron would likely occur close to mineheads where cheap renewable electricity was available, and hot bricketed iron would be imported to the electric arc furnaces for speciality and high-economic merit steel making in the port area. The CO2 stream of million tons per year would nicely fit the demands of the country’s greenhouses, which currently get their CO2 for enhanced crop yields from their natural gas combined heat and power generators. Small distances for small CO2 pipelines to rural destinations will often pencil out, but there’s still a significant question of whether they’ll achieve permitting, or the CO2 would be required to be sequestered offshore for safety reasons. The port is, after all, a major urban area with 2.7 million citizens.

Biogas and biomethane upgrading is an emerging fit. Digesters, landfills, and wastewater plants already separate methane and CO2 to meet gas grid specs. The separated CO2 is usually vented. Where a cluster sits near storage or a terminal, adding dehydration, compression, and logistics for that concentrated CO2 can deliver durable removals from genuinely biogenic streams. The barrier is scale and aggregation. Most sites are small. The solution is hub design that pools multiple streams to shared storage service. Compared to direct air capture, the cost per ton should be lower because the separation is already done. Compared to planting programs, permanence and monitoring can be stronger if storage governance is mature.

Biomethane deserves a place in industrial decarbonization, not as a daily energy vector but as a strategic feedstock that closes several loops at once. Capturing methane from landfills, wastewater treatment plants, and agricultural lagoons prevents a short-lived but potent greenhouse gas from escaping, while purpose-built biodigesters can handle waste biomass that would otherwise decompose anaerobically and emit the same methane uncontrolled. When this carbon is turned into biomethane, cleaned, and fed into industrial systems, it becomes a controllable input rather than a climate liability. The residual digestate carries valuable nitrogen, phosphorus, and potassium that can return to soils, replacing synthetic fertilizers and maintaining nutrient cycles in farms, forests, and grasslands. In my opinion, this closes both the carbon and nutrient loops: biomethane addresses the anthropogenic methane problem while delivering a feedstock that can support essential industries like ammonia, methanol, and direct reduction ironmaking, and can serve as a limited reserve for power systems during dunkelflaute conditions when wind and solar output sag. It is not a substitute for electrification or a fuel for daily combustion, but an industrial backbone material that turns waste into a managed resource.

BECCS in biomass power and municipal waste incineration does not meet the bar. The claim is negative emissions from biogenic carbon captured at the stack. The books do not balance when you include supply chains, land use change risk, foregone carbon storage in forests, and the energy penalty of capture. Shipping pellets across oceans to burn for power and then running capture on dilute flue gas cannot compete with new wind and solar feeding electric heat and storage. It fails even if the capture unit runs to spec because the upstream emissions and opportunity costs eat the supposed negatives. Assertions that forestry waste is a clean feedstock for far-away boilers do not survive scrutiny of moisture, collection logistics, nutrient cycling, and habitat impacts. The better solution is to stop burning the material and to build clean electricity and heat directly. If districts need heat, large heat pumps on clean grids beat BECCS on cost per ton and system value.

The competition test decides what survives. Ethanol fermentation CCS beats not capturing because it is cheap, clean, and near storage in several regions. Ammonia capture beats waiting for cheap green hydrogen where plants already exist at ideal locations. Process capture on cement and lime beats doing nothing in the near term where novel binders are not ready for full market substitution. Biomethane DRI will work regionally as the most cost competitive option over alternatives such as molten oxide electrolysis, flash iron making and hydrogen direct reduction. BECCS does not beat wind, solar, and heat pumps. General fossil combustion CCS does not beat renewable generation that removes the combustion in the first place. Mineralization schemes that move mountains for small gains do not beat re-engineering the process to avoid emissions.

Geography and risk round out the picture. Projects with short pipes across farmland to deep saline formations are one thing. Liquid CO2 pipelines through cities are another. Public safety, routing, and emergency response for densely populated corridors are not solvable at the scales imagined by some hub proposals. Offshore storage from waterside plants avoids much of this and is the path for the North Sea rim. On-site storage under industrial plots in the right basins is the path in parts of North America. Good projects work with the map, not against it.

Sublime Systems belongs in the forward portfolio because it changes the cement chemistry. Its electrochemical route directly works on quicklime-bearing materials including limestone and demolished concrete waste to extract the quicklime, and produces a cold stream of pure, pressurized CO2. Similar thinking applies to electrified calciners that isolate a clean CO2 stream and to next-generation lime processes. These have the potential to make geographically lucky cement plants pencil out against the various levers reducing and substituting demand.

Future growth for CCS should target three buckets. Fermentation and biogas clusters that store biogenic CO2 near sinks. Ammonia and other chemical plants that already separate CO2 and sit on piers or basins. Re-engineered process capture in cement, lime, and biomethane ironmaking where the stream is clean and the storage is close. These are coherent with a grid that is getting cleaner every year, with electrification strategies across heat, mobility, and industry, and with policy that rewards real tons stored. They also build storage governance and monitoring capacity that later supports harder problems, if we still have them.

The thesis is simple. CCS is not a general climate solution. It is a narrow tool for specific flows where chemistry gives you concentration, geography gives you storage, and policy gives you value. Focus there and you get real reductions at tolerable cost. Spread it thin across diffuse sources and you get cost without impact. The niches are enough to matter for ethanol, ammonia, cement and lime, biomethane steel, and some biogenic streams. Everything else should be solved by stopping the emissions at the source with clean electricity and better processes.

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy